Top Quality Wave Soldering Pallet Material: RICOCEL®

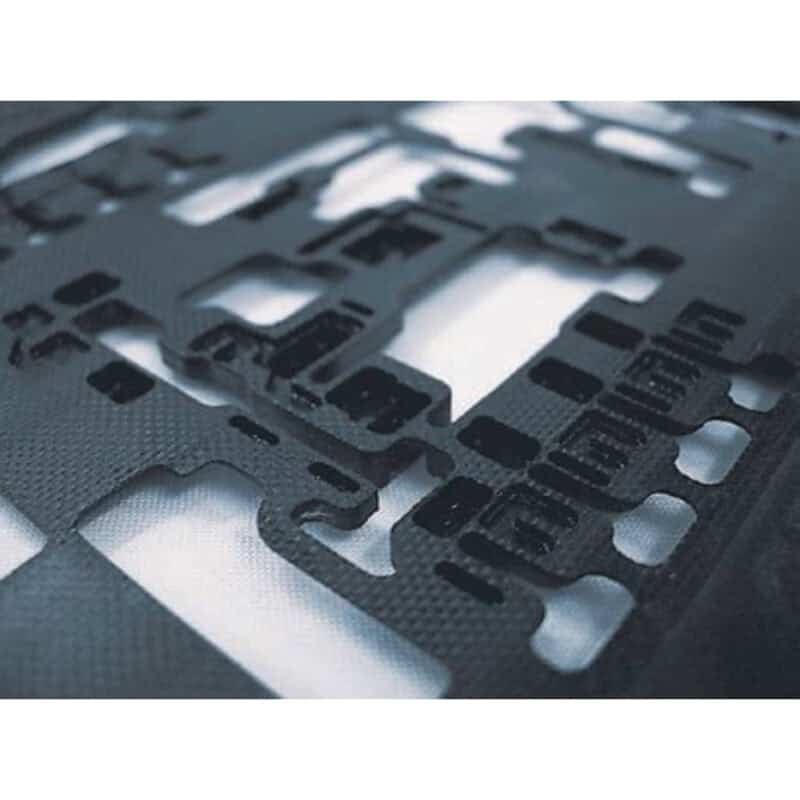

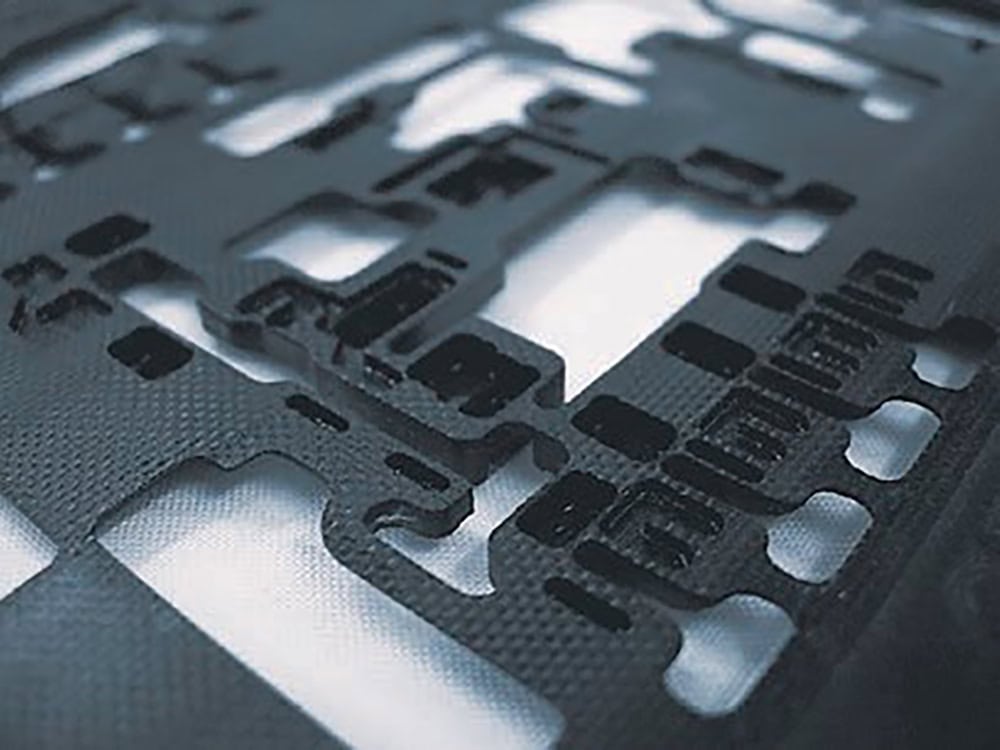

RICOCEL® is the industry leader in Antistatic (ESD) Solder Pallet material, specifically engineered for Wave Soldering and Surface Mount Technology (SMT) reflow process applications. Our RICOCEL materials are made from advanced Glass/Epoxy laminates, offering superior heat resistance, stable antistatic properties, excellent machinability, enhanced durability, and robust chemical resistance.

“We are the only distributor for Ricocel wave soldering pallet in Malaysia”

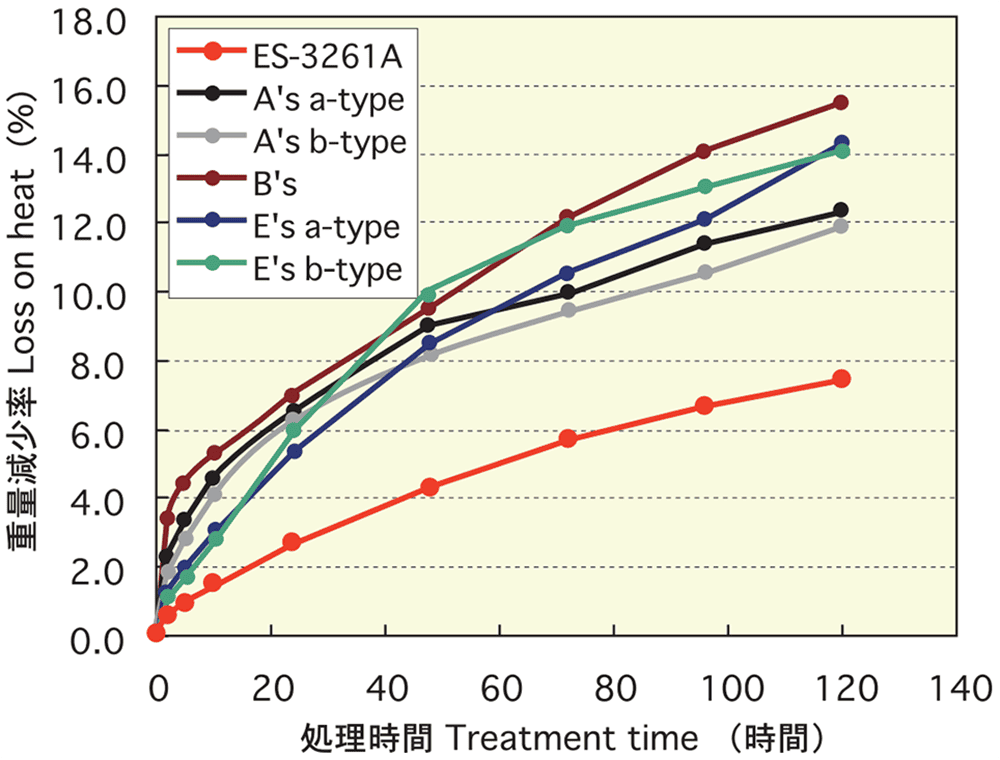

Loss of weight from High heat is one of the test items to show degradation in resin-base material.

Ricocel solder pallet has a much lower reduction in weight compared to other brands’ pallet material in the market.

Why Choose RICOCEL® Solder Pallet Material?

- Superior Heat Resistance: RICOCEL® solder pallet material is designed to withstand extreme temperatures, ensuring reliability in high-heat soldering environments.

- Stable Antistatic Properties: Our materials maintain consistent ESD protection, essential for safeguarding sensitive electronic components.

- Chemical Resistance: Engineered to resist aggressive chemical fluxes, RICOCEL® ensures long-lasting performance.

- Proven Durability: RICOCEL® pallets can withstand more than 10,000 cycles of repetitive soldering, showcasing their exceptional durability.

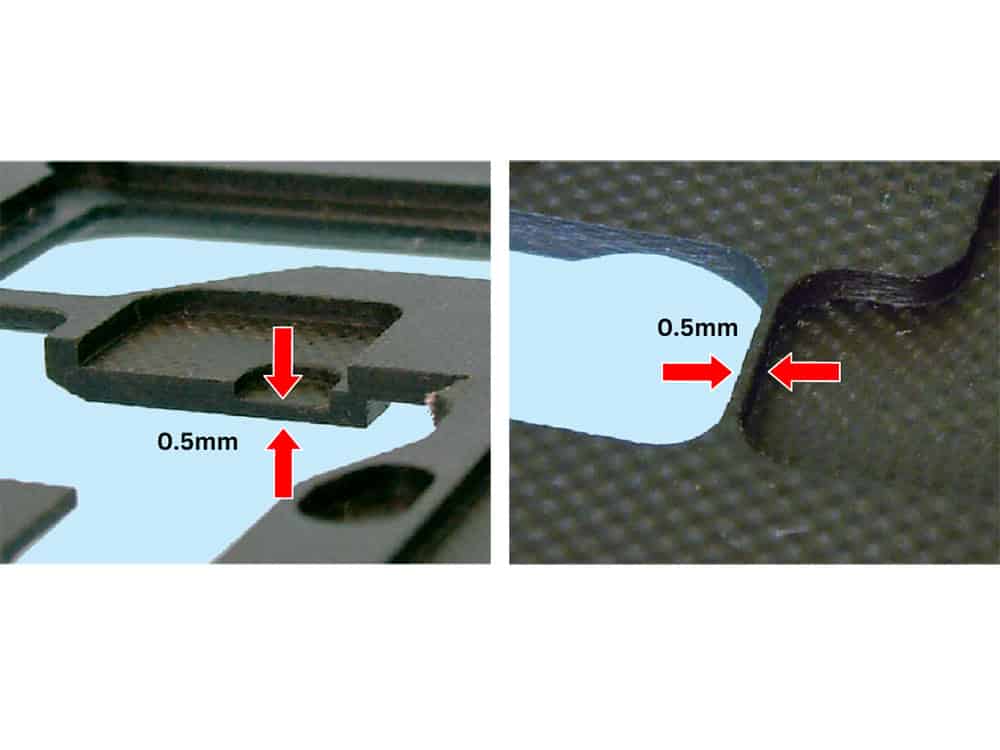

- Mechanical Strength: Even thin-wall or thin-bottom parts of RICOCEL® pallets exhibit excellent mechanical strength.

- Cost Efficiency and Productivity: The excellent durability and robust performance of RICOCEL® materials reduce the need for frequent replacements and ensure sustained operational efficiency, leading to lower overall costs and increased productivity.

RICOCEL® Solder Pallet Material

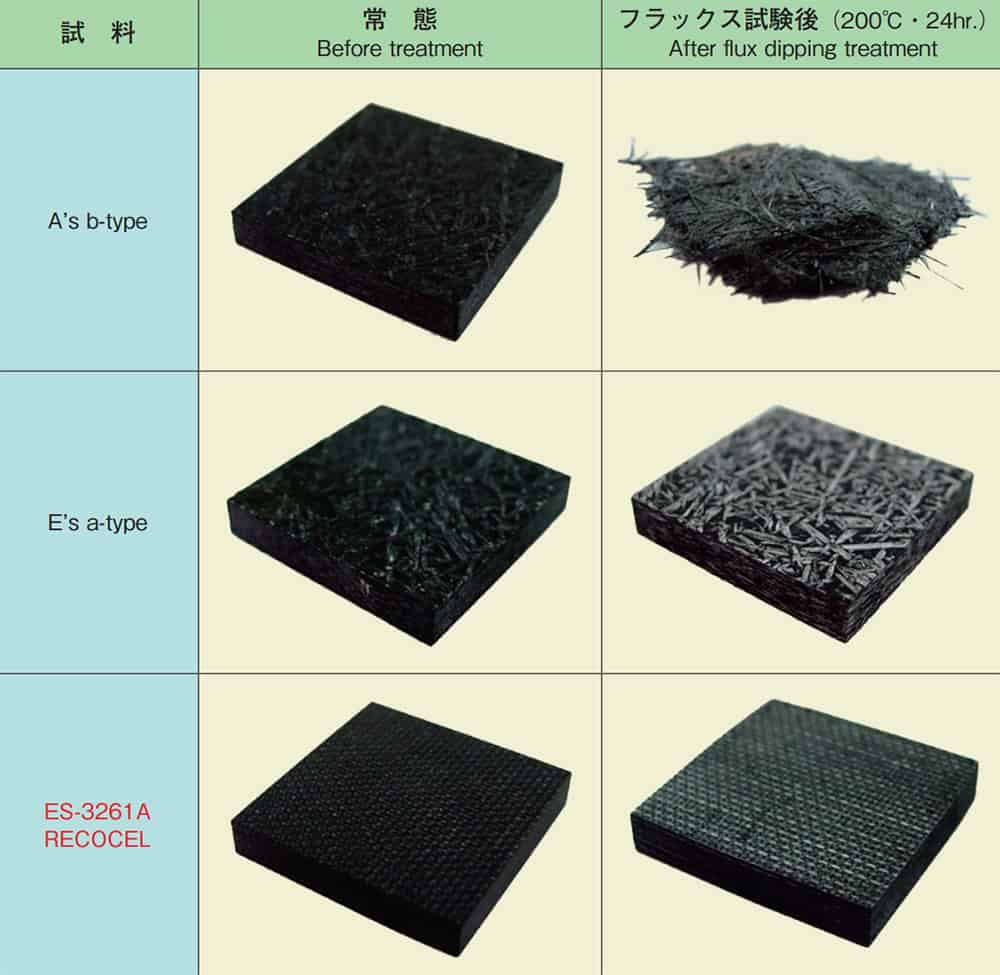

Ricocel is engineered to offer exceptional chemical resistance, effectively withstanding soluble flux.

RICOCEL® Solder Pallet Material

Widely Trusted by EMS Providers

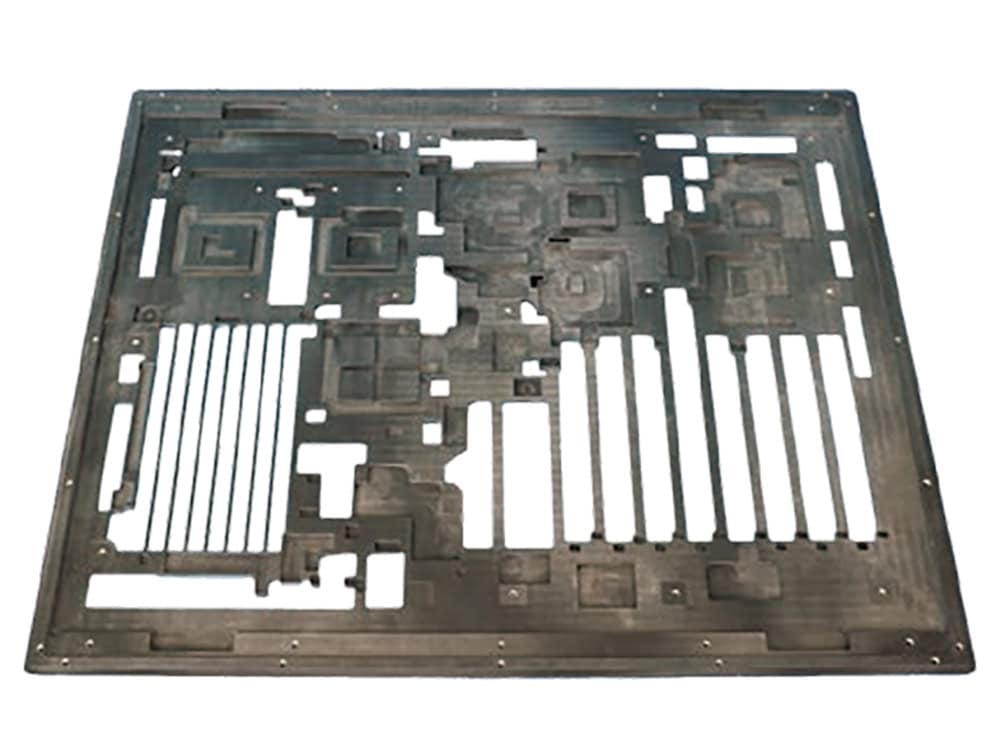

Major Electronic Manufacturing Services (EMS) providers prefer RICOCEL® for its extended cycle times and minimal maintenance requirements. Production operators appreciate its efficiency, which translates to increased productivity on the production line.

The Preferred Choice for Wave Soldering and SMT Reflow Processes

Across industries reliant on wave soldering and Relfow processes, RICOCEL® is the preferred choice for solder pallet material. Its superior properties and proven track record make it the top option for manufacturers looking to enhance their production capabilities.

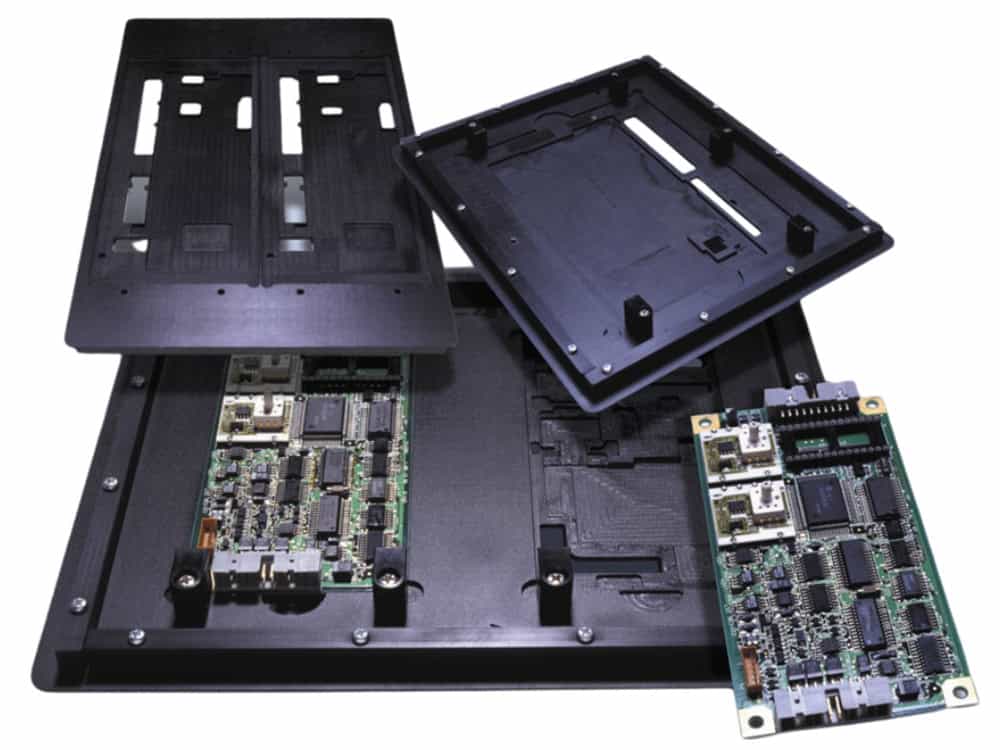

Ricocel Wave Soldering Pallet

Ricocel Wave Solder Pallet with Antistatic properties for Wave and Reflow Soldering.