Applications:

- In the factory to confirm stacks of glass: If crates are unmarked, the SG2700 can offer a quick test to ensure the glass has been processed (strengthened). This can be helpful at the glass processing plant where the glass is tempered or the assembly plant where the windows are being constructed. This test certainly beats the alternative destructive test of breaking a piece of glass to see if it has been processed.

- In the field to confirm strengthened glass in windows: This is necessary when the tempered stamp on the window's bottom corner is forgotten or hidden behind the jamb.

- Window replacement applications: When replacing a window, determine whether the glass is tempered to reorder and replace it with the correct product. It is not uncommon for older windows to not contain any stamp indicating whether it's tempered glass on the bottom corner of the window.

- Window tinting applications: Tinters often need to know if the windows they are about to tint contain tempered glass. It could impact the type of film selected for the project.

- IG repair (seal failure): It is necessary to know whether the windows being repaired contain tempered glass, as repair technicians cannot drill holes into the tempered glass.

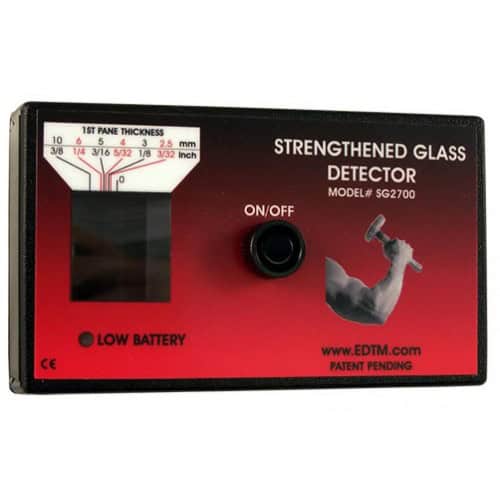

- Building inspectors and architects: The SG2700 is the perfect tool to spot-check windows on a job site and to check incoming windows to confirm the product has been appropriately labeled.

Important Information about Strengthened Glass

ASTM C-1048 and ANSI Z97-1, and 16CFR1201 specify three classifications for Strengthened Glass:

Strengthened Classification Surface Compression

Heat Strengthened Glass..................................3500 - 7500 psi

Tempered glass.................................................> 10,000 psi

Safety Glass.........................................................15,000 - 22,000 psi

The SG2700 Strengthened / Tempered Glass Detector does not differentiate between these classifications. It confirms that the glass has been strengthened in one of the three capacities. See the user manual for more details.

Slide the meter across the glass and conveniently watch the reflections from the glass head-on. As the meter crosses stress lines in the glass (caused by the strengthening process), the resulting surface reflections from our wide array of light sources will change color. The unique optics of the SG2700 provide a vivid change in color and is excellent for applications where the stress lines are more challenging to view.